Rubber Lining

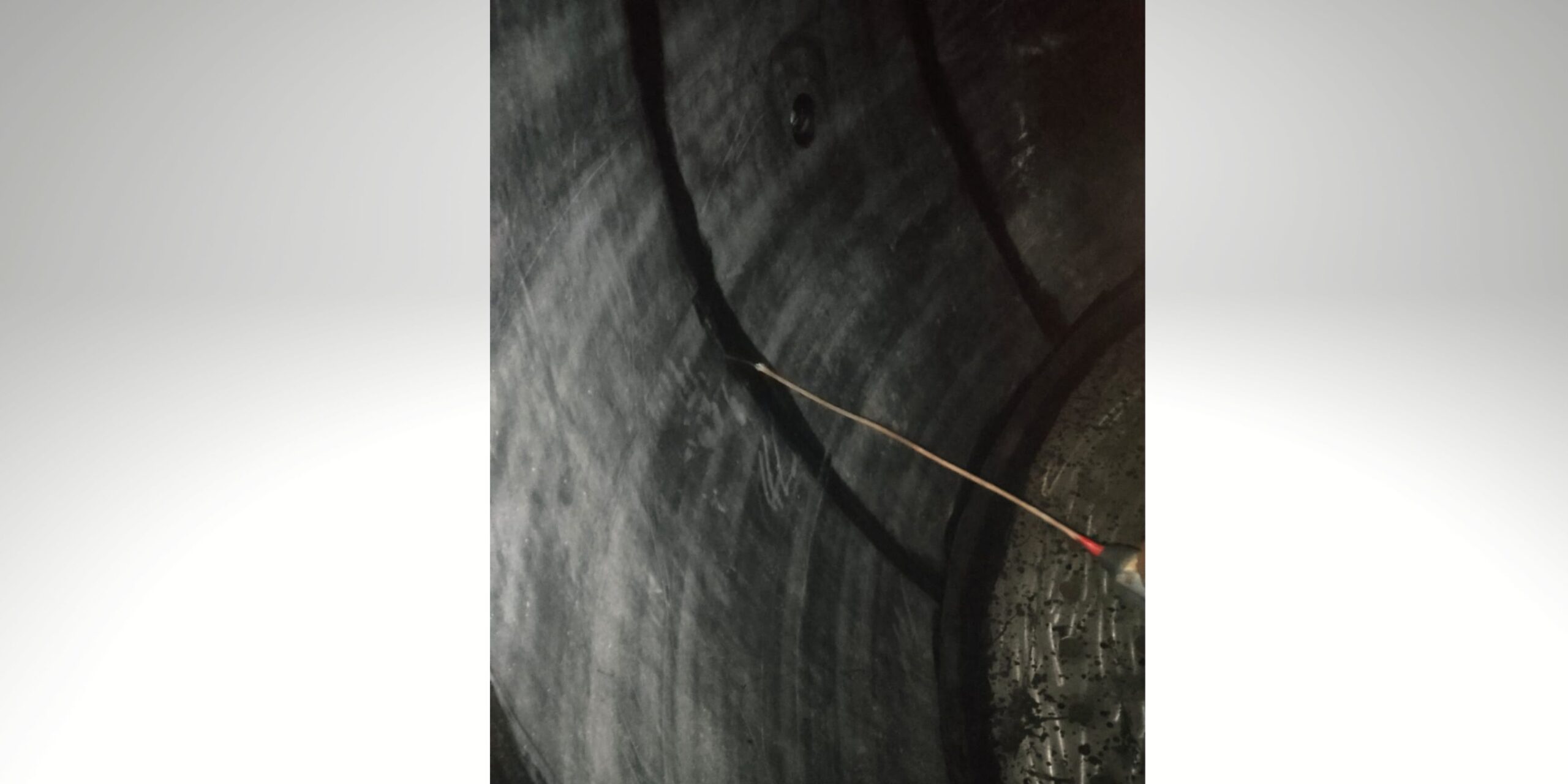

Rubber Lining is an application method used to protect multiple types of systems by lining corrosion and abrasion-resistant rubber upon the surface or inside of pipes and tanks.

Rubber Lining is a very niche skill. A rubber liner, lines interior of tanks, valves, pipes, and similar articles with rubber sheeting to prevent corrosion of vessel, and to minimize contamination, shock, ignition, or explosion hazards to contents.

Rubber-lined pipes are used to transport Abrasive Slurry solutions, Corrosive Chemicals, and many other liquids from one place to another. Without the rubber lining, the pipes would corrode, causing leakages and losses.

A wide range of rubbers and elastomers are available for lining vessels, tanks, and piping. Rubbers can also be made with anti-static properties to give a low surface electrical resistance. Hard rubbers, i.e. hardness greater than Shore D 60, can only be applied by autoclave vulcanization, and therefore hard rubber lining is restricted to small equipment or components. Only soft rubbers can be applied on site.

Detailed designs can be brought from us or are included in the cost of manufacturing when buying direct from us.